-

PPD-AFTM

-

Fully automatic aluminum foil tray making machine is a production line,it is included feeding machine, high accuracy press, scrap collecting system, stacker.

Features:

1.The machine adopts PLC as the controlling system.

2.The feeding length, producing speed and other parameter are easily set, this integration of Gas& Electrical centralized control, automated production.

3.The feeding is controlled by stepper system, the feeding length is accurate And can be adjusted freely from 20m to 999m.

4.The high accuracy press adopts steel plates joining body, variable frequency speed regulation, dry type friction clutch-on-off, rigid over-load protector to protect the press.I.Feeding machine

Max.Width of Roll 350mm 500mm 650mm 750mm Max.Unwind Roll Diameter 600mm 600mm 600mm 600mm Feeding Speed 0-35 m/min 0-35 m/min 0-35 m/min 0-35 m/min Feeding Length 20-999mm 20-999mm 20-999mm 20-999mm Feeding Accuracy ±0.3mm ±0.3mm ±0.3mm ±0. 3mm Voltage 220/380/415 V 220/380/415 V 220/380/415 V 220/380/415 V II.High Accuracy Press

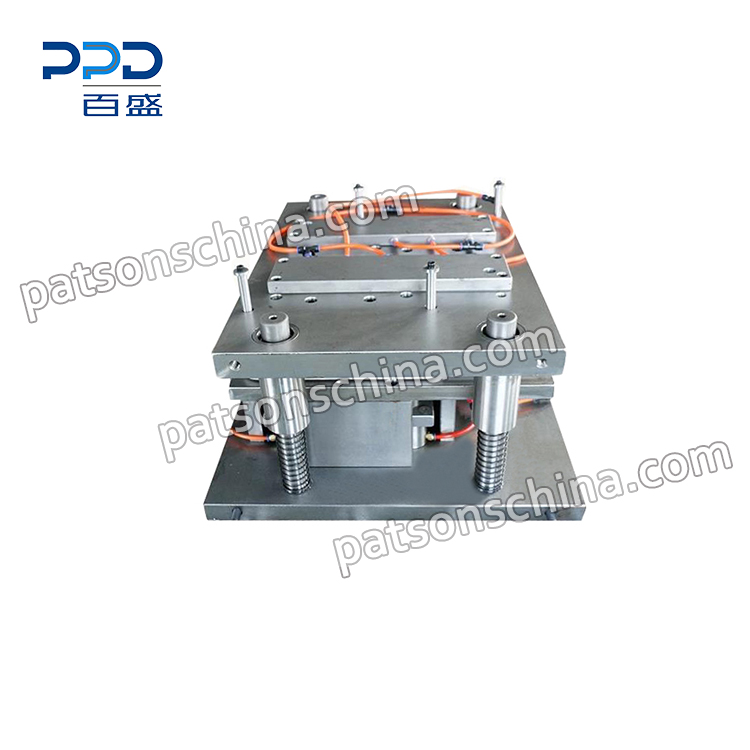

Model PPD-45T PPD-63T PPD-80T PPD-110T Nominal Pressure 450KN 630KN 800KN 1100KN Slide Block Strok 100-260mm 120-260mm 140-260mm 150-260mm Slide Stroke Per Minutes 70-50/min 70-50/min 60-45/min 50-40/min Maximum Die Set Height 270-400mm 310-450mm 325-450mm 345-500mm Die Set Height Adjustment 60mm 70mm 80mm 90mm Slide Bottom Size 410*340mm 480*400mm 560*460mm 630*520mm Stemhole Size φ60*60mm φ60*65mm φ60*75mm φ60*85mm Bolster Surface Size 810*440/990*750mm 870*520/1000*800mm 1000*600/1200*800mm 1100*680/1300*800mm Total Power 5.5kw 5.5-7.5kw 7.5-11kw 11-15kw III.Mould

IV.Scrap Collrcting Device